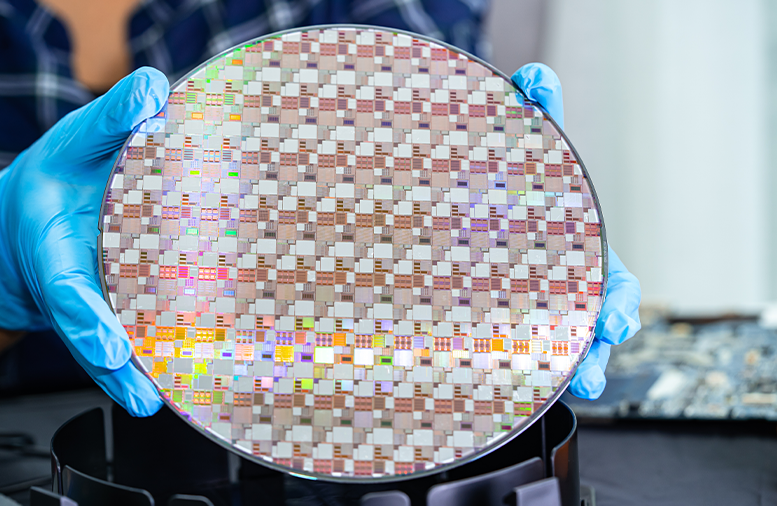

In the microelectronics and semiconductor industry, etching is a crucial step in the chip manufacturing process, determining the precision and performance of the circuits. The etching process is generally divided into two main categories: wet etching and dry etching, each with its unique applicable scenarios and advantages.

Wet etching uses liquid chemical reagents (etching solution) to chemically react with the material being etched, selectively removing the unwanted parts of the material's surface. This process typically involves immersing the wafer to be processed in the etching solution and precisely controlling the depth and profile of the etching by adjusting parameters such as temperature, concentration, and time. Wet etching has the advantages of simple equipment and low cost, but it may not match dry etching in terms of precision and control of complex patterns.

Dry etching does not rely on liquid media but instead uses gases (such as fluorides, chlorine, etc.) or high-energy ion beams (such as plasma) to undergo physical or chemical reactions with the material's surface, thereby removing the material. Dry etching includes various techniques such as reactive ion etching (RIE), deep reactive ion etching (DRIE), and plasma etching. These techniques can provide higher etching precision, better control of vertical sidewall profiles, and the capability to process more complex patterns, making them highly popular in the manufacturing of high-precision, high-performance integrated circuits.

Etching process implementation steps:- 1.Pattern definition: First, a layer of photoresist is applied to the surface of the wafer, and the designed circuit pattern is transferred to the photoresist through the photolithography process. This step serves as the "template" for the subsequent etching.

- 2.Pre-etching treatment: This includes cleaning the wafer surface, removing impurities, and ensuring the purity and consistency of the etching process.

- 3. Etching: According to the selected wet or dry etching technique, the wafer is etched to remove the material in the areas not covered by the photoresist.

- 4. Post-etching treatment: Remove the remaining photoresist and other residues, check the etching quality, and perform necessary cleaning and drying.

- 5. Subsequent processes: After completing the etching, additional processing steps may be required, such as depositing metal layers, annealing, etc., to construct a complete circuit structure. Technologies are also continuously evolving to meet the growing demand for smaller and more highly integrated electronic products.

As a core technology in microelectronics manufacturing, the precision and reliability of etching are crucial for the performance and yield of chips. With the advancement of technology, etching techniques are continually evolving to meet the growing demand for smaller and more highly integrated electronic products.