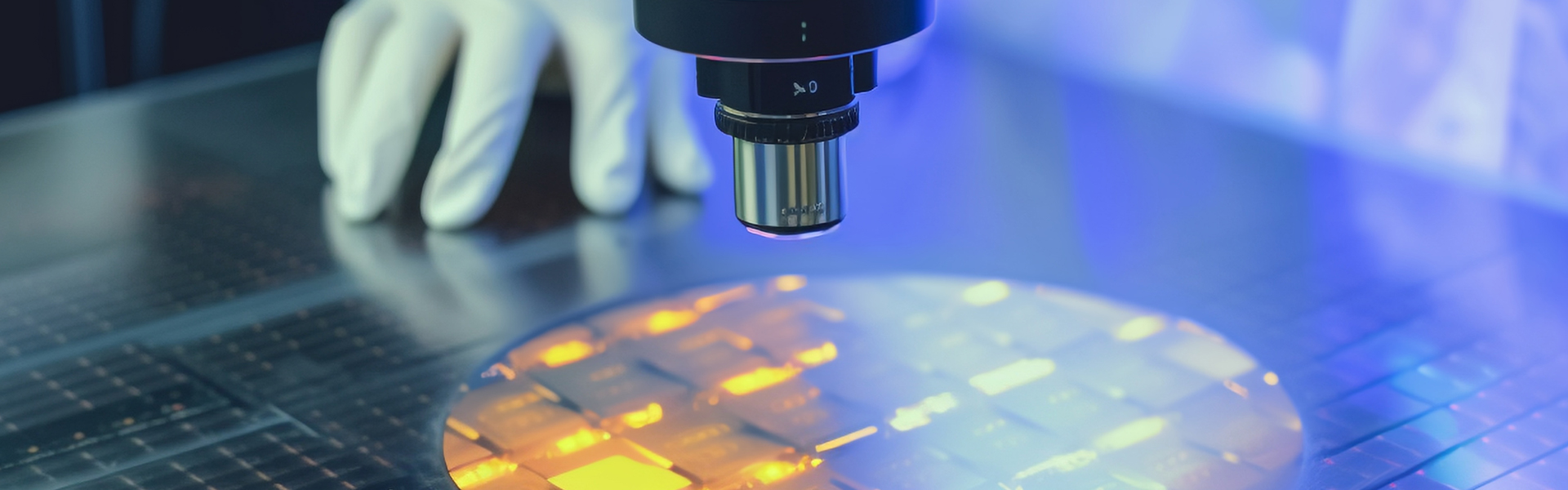

The plasma etching machine is one of the core devices in semiconductor processes. In semiconductor manufacturing, it uses plasma energy to finely process silicon wafers, which is a key step in the production of microelectronic devices. Plasma etching machines have high precision and can create extremely complex patterns at the microscopic level. The application of plasma etching machines in the semiconductor industry is very extensive. They can be used not only for etching semiconductor materials such as silicon and phosphorus but also for manufacturing chips and circuits. In addition, plasma etching machines play an important role in fields such as microelectronics, micro-electromechanical systems (MEMS), and nanotechnology applications.

Reactive ion etching (RIE) is a dry etching technology that operates on the principle of using molecular gas plasma for etching in a vacuum system. This process involves applying high-frequency voltage between flat electrodes to generate an ion layer, where the sample is placed, and ions collide with the sample at high speed to complete the chemical reaction etching. RIE technology achieves anisotropic etching through ion-induced chemical reactions, which means that ion energy creates a damaged layer on the surface of the etched layer that is easier to etch and promotes chemical reactions. At the same time, ions can also remove surface byproducts to expose a clean etching surface. This etching technology is characterized by high selectivity and high etching rates, and it is widely used in the fine processing of chip manufacturing and other fields.

Materials such as carbon oxides, nitrides, tantalum nitride, titanium nitride, etc

Two, three, four, eight inches

-20°℃~100℃

Integrated Circuit and Chip Manufacturing, Micro Electro Mechanical Systems (MEMS) Manufacturing, Biomedical Applications