Turbomolecular pump is a vacuum pump that uses a high-speed rotating impeller to transfer momentum to gas molecules, causing directional flow and pumping of gas. The main function of a turbomolecular pump is to generate and maintain high vacuum in a vacuum system. By the interaction between the high-speed rotating impeller and gas molecules, gas molecules are extracted from the vacuum system, thereby achieving the goal of reducing the internal gas pressure of the system.

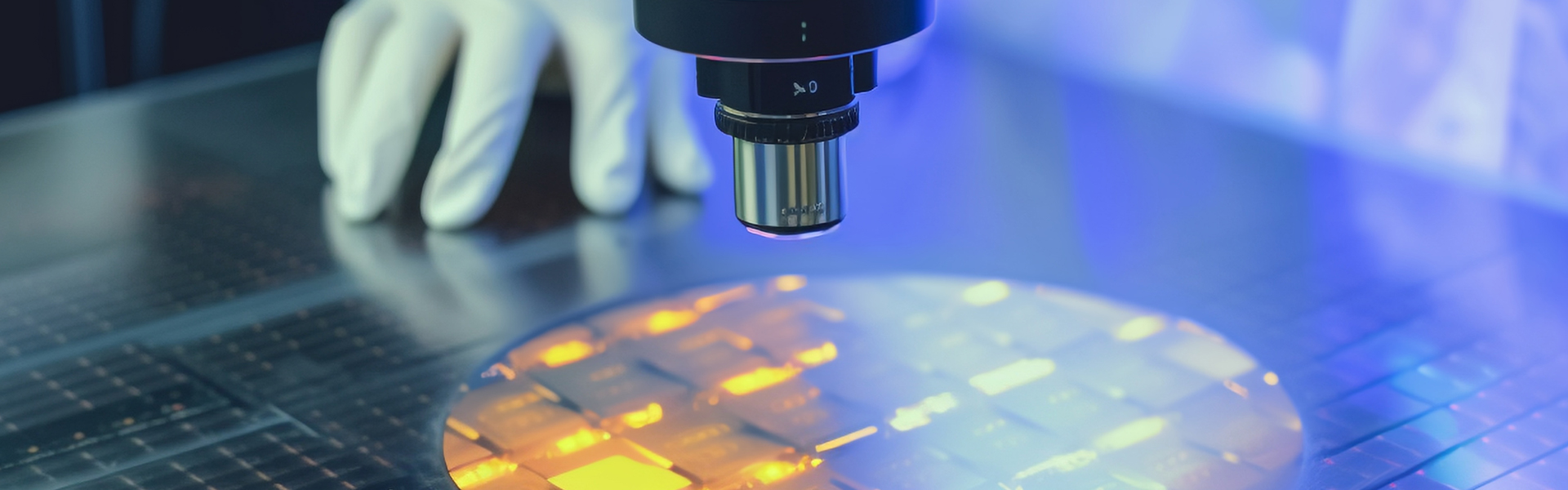

Turbomolecular pumps are widely used in various fields due to their high efficiency, cleanliness, and oil-free characteristics 1. High energy accelerator: In particle accelerators, a very high degree of vacuum is required to reduce collisions between particles and gas molecules, thereby improving acceleration efficiency and accuracy. Turbomolecular pumps can meet this demand by providing a stable vacuum environment for accelerators. 2. Controllable thermonuclear reaction device: In nuclear fusion reactions, high temperature and high pressure environments require extremely high vacuum levels to reduce the impact of impurities on the reaction. Turbomolecular pumps can ensure high vacuum in the reaction chamber, thereby ensuring the smooth progress of nuclear fusion reactions. 3. Heavy particle accelerator: Similar to high-energy accelerators, heavy particle accelerators also require high vacuum to reduce collisions between particles and gas molecules. Turbomolecular pumps play an important role in this regard. 4. Vacuum coating: During the vacuum coating process, it is necessary to maintain a high vacuum degree in the vacuum chamber to prevent gas molecules from affecting the coating quality. Turbomolecular pumps can provide a stable vacuum environment to ensure the smooth progress of the coating process. 5. Advanced electronic device manufacturing: When manufacturing advanced electronic devices such as semiconductor chips, it is necessary to maintain a high vacuum level in the production environment to prevent impurities from affecting device performance. Turbomolecular pumps can meet this demand and provide a clean vacuum environment for electronic device manufacturing. Features and advantages: 1. Fast start-up: Turbomolecular pumps can quickly start and achieve stable pumping effects in a short period of time. 2. Anti radiation exposure: able to resist various types of radiation exposure, suitable for research fields such as high-energy physics and nuclear fusion. 3. Resistance to atmospheric impact: able to withstand the impact of atmospheric pressure on the pump, ensuring stable operation of the pump in harsh environments. 4. No gas storage and desorption effect: Turbomolecular pumps do not store gas molecules during operation, nor do they release gas molecules after stopping, thus avoiding the impact of gas desorption effect on vacuum degree. 5. Oil free vapor pollution: Due to the fact that turbo molecular pumps typically use oil-free lubrication systems, there will be no oil vapor pollution issues.