PL-200(ICP)Inductively coupled plasma etching machine has a wide range of applications in many fields, mainly including, in the field of electronics and communication technology can be used for silicon dioxide, strained silicon, silicon carbide, polysilicon gate structure, III-V compound and other semiconductor materials, as well as metal wire, metal welding pad and other metal materials. In the field of mechanical engineering, it is often used for deep groove etching of silicon materials, and shallow silicon etching in MEMS (micro-electromechanical system) surface technology. In addition, it also has potential application value in nanotechnology, biotechnology, optical technology and other fields.

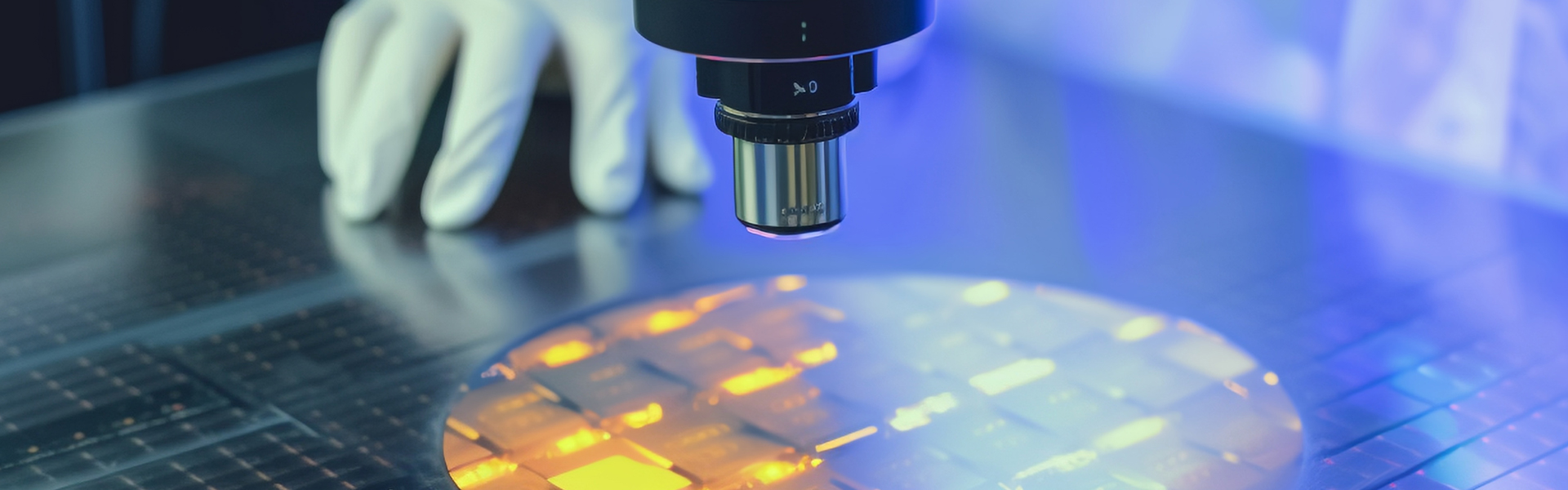

ICP inductively coupled plasma etching machine through the lower electrode RF generator and inductively coupled ion RF generator to ionize the process gas in the vacuum chamber, thereby producing high-density plasma to achieve rapid etching of various medium materials, metals and compound semiconductors and other materials (such as silicon oxide, silicon nitride, metal, Group III materials, etc.). The equipment is composed of a pre-vacuum chamber and a reaction vacuum chamber, which minimizes the contact between the material and the outside world and ensures a safe operating environment for the operator. Inductively coupled plasma etching machine (ICP) is mainly composed of the following parts: reaction chamber, upper electrode, lower electrode, RF source, vacuum system, reaction gas control system, refrigeration system, back helium control system, equipment operating software, supporting accessories, etc.

Configure 8 gas pipelines

2 inches

Electronics and Communication, Mechanical Engineering, Micro Electro Mechanical Systems, Nanotechnology, Biotechnology, Optical Technology

Various dielectric materials, metals, and compound semiconductors (such as silicon oxide, silicon nitride, metals, III-V materials, etc.)