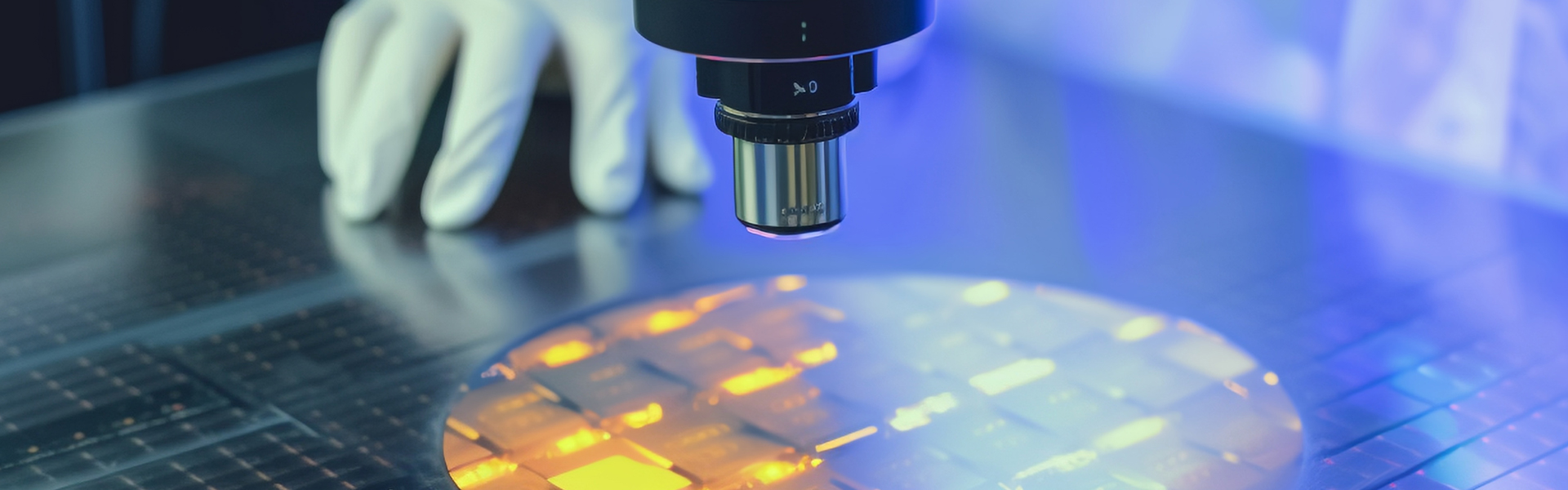

The IBE-75 ion beam etching machine plays a key role in various high-tech and industrial fields, such as semiconductor manufacturing, microelectronics and optoelectronics, MEMS (Micro Electro Mechanical Systems), biomedicine, nanomaterial preparation, data storage and magnetic recording, and aerospace, due to its high precision and high controllability. It uses high-energy ion beams to bombard the surface of materials, causing atomic sputtering and achieving the purpose of etching. This etching technique can produce extremely fine device structures, improve the performance and stability of chips, and also create nanoscale structures on the surfaces of various materials, such as nanowires, nanopores, etc. This is of great significance for fields such as nanoelectronics and biomedical research. In addition, ion beam etching machines can also be used for the manufacturing of optical devices, to perform micro treatments on the surface of optical devices, improve surface quality, manufacture fine structures, and thereby enhance the performance and efficiency of optical devices.

The principle of the ion beam etcher is to use the ions generated by the ion source to form a high-energy ion beam after being accelerated and focused by an electric or magnetic field, and then accurately target and bombard the surface of the sample to be processed. This physical bombardment results in the removal or movement of surface atoms, enabling precise etching of the sample surface. During the etching process, there is usually a mask to protect the part that does not need to be etched to ensure the formation of the desired groove or pattern. Ion beam etching machine has the advantages of high precision, strong controllability and wide application range, so it has been widely used in nano-machining, chip manufacturing, optical component preparation and other fields. By precisely controlling the energy, dose and irradiation time of the ion beam, the sample can be accurately processed to meet the requirements of various complex structures and high precision.

| Model number | IBE-75 |

| Ion source | Kaufman ion source; The diameter is 100mm, which is calibrated according to the inner diameter of the anode cylinder. 1) Adjustable range of ion energy: 0 ~ 1000eV; 2) Adjustable range of ion beam: 0 ~ 100mA; The ion energy and beam current can be matched automatically. 3) Effective beam diameter: b ≥76mm (3 inches); The inhomogeneity of etching within the diameter range is ≤±4%. |

| Etching table | 1) Cooling method of sample table: water cooling; Can be installed 3 inches and below sample 2) Etching Angle range 0°~90° adjustable. 3) The rotation rate of the sample table is 9rpm |

| Vacuum system | Vacuum chamber: SUS304 stainless steel 1) High vacuum system: pre-stage vacuum pump + molecular pump; 2) Limit vacuum: PLim≤8.5×10-5Pa(no cold trap, no baking); 3) Working gas: ordinary nitrogen, process gas route 1-2; 4) Vacuum measuring system: composite vacuum gauge, resistance vacuum gauge + ionization gauge. |

| Ion source power supply and automatic control system | 1) The ion source power supply is designed according to the unique multi-system formula of the power supply, and the external characteristics of the power output are highly matched with the dynamic load of the ion source, so that the ion source is in an efficient and stable operation state. 2) Full automatic + semi-automatic control; Support single process and multi-process group, operation record, operation record, fault diagnosis, alarm and other functions. |

6 inches

This system is a universal ion beam etching system that can not only perform traditional three-dimensional structure etching, but also achieve functions such as ion beam cleaning, ultimate polishing of material surfaces, and material thinning. It can also be optionally equipped with reactive ion beam etching (RIBE)

Various new materials and devices in fields such as semiconductors, optics, microelectronics, micromechanics, communications, navigation, satellites, radar, nuclear fusion, superconductivity, etc., including sound, light, electricity, heat, magnetism, etc

Various metals, alloys, non metals, oxides, nitrides, carbides, semiconductors, polymers, ceramics, infrared and superconducting materials, etc